The productive demand in the industrial sector is greater every day. The levels of consumption at present, the constant population increase, and the economic growth of certain regions force this sector to produce more in less time. Said merchandise must, in turn, go through a strict process of engraving, marking, and coding to keep precise control of the product, for which new technologies have been essential to achieving such objectives.

As we know, technology is increasingly responsible for optimizing industrial production processes. More and better procedures are constantly emerging that greatly speed up manufacturing, product quality, and respect for the environment; this has also been an important edge in recent years.

In previous articles, we have emphasized that one of the technologies the industry has taken the best advantage of is laser machines. Today, these are found in almost all industrial sectors and are used for welding, cleaning, cutting, and engraving or marking.

It is precisely laser engraving and marking that we want to talk about in this article because although it is a technology that is still relatively new, improvements in optical systems have recently emerged, allowing the capabilities of this tool to be greatly expanded.

In this publication, we will remember what it is and how it works, in which materials it can be implemented. Finally, we will mention the industry’s main applications of laser marking.

What is laser marking, and how does it work?

It is a technology that uses the laser beam to implement permanent marks of different types on a determined surface so that it does not alter its shape or structure. A previously processed design designed with simple software is obtained with the laser beam’s energy.

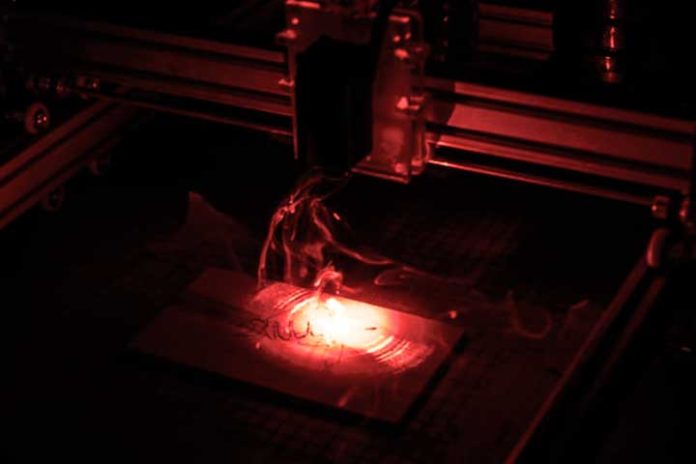

The laser beam is focused on a material and slightly vaporized in its superficial layer, obtaining the desired design with a specific pattern. This process is non-contact, fast, and with the possibility of using designs with highly sharp details. With a fibre laser, different materials can be worked with the same machine; it is also a respectful process for the environment since no pollutants are generated.

In this sense, this is one of the most versatile technologies to guarantee the legibility and durability of product marking or coding. So much so that, currently, there are endless applications in the industrial field; this is because, unlike laser engraving, the action of the laser is less deep, which allows an application in a large number of materials without the risk of cutting or altering the structure.

We will comment below some of the common materials used daily in all types of industry and which can be perfectly laser marked:

- Stainless steel

- Aluminium

- Precious metals (gold, silver, bronze)

- Brass

- CVP

- ABS plastic

- Polycarbonate

We are considering how it works and what types of materials can be used to make getting an idea of laser marking applications in the industry much easier. In the same way, we will tell you which are the main and most demanded in this sector.

Main applications of laser marking in the industry

Auto parts for the automotive industry

The traceability and identification of parts and auto parts using laser marking have undoubtedly meant a before and after as far as the production of locomotion vehicles is concerned. Not only because they guarantee faster and more efficient coding and classification, but it has also become one of the best alternatives to ensure the brand’s authenticity.

Medical and healthcare industry

Due to its nature and scope of application, everything that includes surgical and sanitary instruments requires strict hygiene measures. This is necessary even from its manufacture. For this, laser marking has been an excellent measure since by doing it without ink or any other component for its serialization or coding, health is guaranteed to a certain extent. In addition, thanks to this marking, the process of inventory control within the health sector is much more adequate and efficient, avoiding the indiscriminate leakage of resources.

Expiration dates in the food and pharmaceutical industry

The production of food, medicines, and articles for hygiene and personal use belongs to the commercial sector most in demand by the world population. And as we know, according to the regulations of each country, they must be marked with an expiration date suggested by the manufacturer. The use of inks, plastics, contact paper, glues, or other materials for this, was forgotten thanks to laser marking. An alternative that, in addition to better adjusting to the need for speed that mass production implies, is more respectful of the environment since it does not generate waste or disposable waste.

Serialized with barcodes and QR

In which the industrial applications of laser marking can be endless. Today, billions of products depend on serialization or coding for their commercialization. If we also add the internal parts or spare parts that often require, we find ourselves before a truly incalculable figure. In this sense, thanks to the ease of reading offered by laser engravings and the number of materials in which they can be used, the industries dedicated to the manufacture of all kinds of technological sections and their components have greatly benefited; We are talking about computers, mobile phones, tablets, household appliances, smart devices, and a long etcetera.

Indeed, we could spend days writing about the applications of laser marking in the industry. However, we consider that in those above, the wide scope that this type of technology offers in large-scale production is described in global terms.